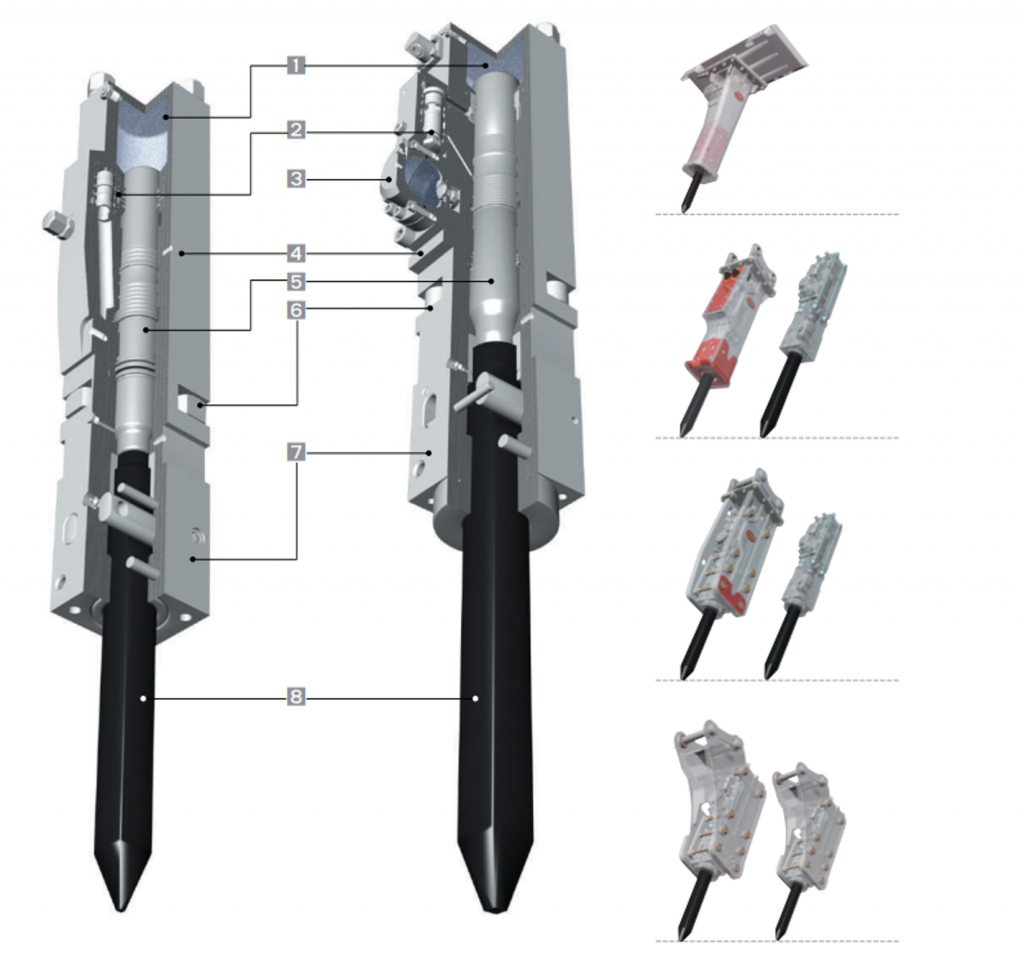

Installed the oil connections (input /output) and the gas valve.

Maximized energy– The nitrogen gas in the back head is compressed once the piston moves upward by the oil pressure and accumulation of the energy, which is converted into the blow energy effectively as the piston descends.

Auto-greasing System– The Auto-greasing system provides working efficiency as well as enhancing breaker durability.

Underwater system– Remote location of air-check valve from the impact point prevents dust influx into the breaker. The underwater operation is available with unique device installation even in the deep water. Combination with Auto-grease device offers improved efficiency.

Structural Safety– The Safety increases efficiency and protection in housing and the valve provides smooth operations and controls functions of the piston.

Cylinder Regulator– The regulator increases working efficiency with regulating the breaker power and the number of impacts by controlling moving distance of the piston.

The accumulator is composed of a rubber film, is compressed by the nitrogen gas in the upper part and is connected with the cylinder at the blow part.

Shock Absorption System– The Shock absorption system enhances equipment durability in the impact and increases efficiency with oil supplements.

The minimum hydraulic system enables the breaker to maximize efficiency for reciprocation of the piston where high and low tension circulates.

Cylinder Stability– The cylinder is manufactured by a precision machinery with the appropriate quality assurance, offering quality satisfaction.

The piston is installed in the cylinder, which converts the oil pressure into the impact power to break rocks.

Durability– Quality proven materials in intensity, anti-wear, heat resistance, tenacity, anti-impact, internal pressure lengthen the life of piston.

Post Management– The appropriate quality assurance system offers quality satisfaction.

The 4 units of the bolts firmly fix the important components onto the breaker.

The Heat-treated tool for breaking rocks.

Moil Point– Suitable for most of demolition, road construction, pier work as well as civil engineering.

Chisel (Wedge Point)- Suitable for most of demolition, concrete cutting as well as tunnel construction.

Blunt– Suitable for mine as well as a quarry